How Does A Planetary Concrete Mixer Work?

Planetary concrete mixers achieve efficient mixing through a combination of rotation and revolution. Their core working principle utilizes a planetary gear transmission system to drive the mixing blades, creating a complex three-dimensional motion trajectory within the mixing drum, ensuring thorough mixing of materials from all angles.

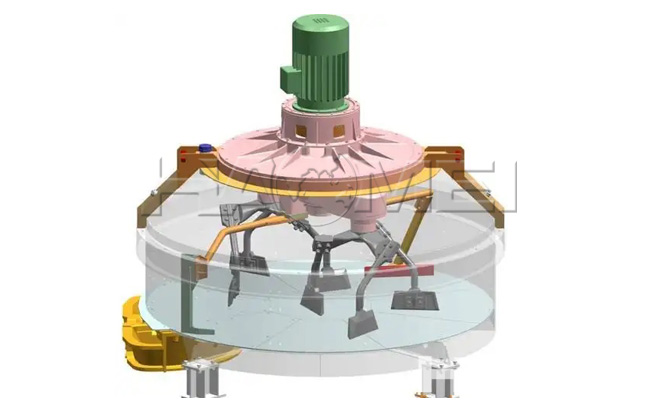

Core structural components of a planetary concrete mixer:

- Mixing drum:

Lined with wear-resistant alloy steel plates to withstand high-intensity mixing friction and extend service life. The drum shape is typically disc-shaped with a vertically arranged axis, available in two types: fixed disc (drum fixed) and rotary disc (drum rotating).

- Planetary transmission mechanism:

Consists of a reduction system composed of a sun gear, planetary gears, and a gear ring, driven by an electric motor to rotate the planetary carrier. The planetary carrier drives the mixing blades to revolve around the mixing axis, while the blades themselves rotate at high speed, creating a combined motion.

- Mixing blade (Turboprop device):

Equipped with 6-8 sets of curved blades. The blade shapes are optimized (e.g., twisted, frame, multi-layered blades) to enhance shearing and kneading effects. Some models are equipped with a high-speed dispersion disc and a wall scraper to further eliminate dead zones in the mixing process.

Composite motion trajectory of planetary concrete mixer:

- Revolutionary motion:

The planetary carrier rotates at a low speed (approximately 6-125 rpm) around the central axis of the mixing drum, driving the agitator to circulate the material over a large area. Revolution causes the material to flow from the edge of the mixing drum towards the center, and then diffuse from the center back towards the edge, forming radial convection.

- Rotation motion:

The agitator rotates at high speed around its own axis (up to 285 rpm), generating strong local shear forces. Rotation causes the material to be repeatedly squeezed and kneaded in the axial and tangential directions, breaking up aggregate lumps and improving uniformity.

- Three dimensional mixing:

The superposition of revolution and rotation forms a spiral composite trajectory, causing the material to exhibit multi-directional motion of "tumbling + shearing + diffusion" within the mixing drum. Simulating the trajectory of a planet orbiting a star ensures that every particle of material is fully mixed, avoiding segregation.

Technical advantages of planetary concrete mixer:

High efficiency mixing:

The mixing cycle is shortened to less than 90 seconds, reducing unit energy consumption by approximately 15%. Mixing time is reduced by 30%-50% compared to traditional twin-shaft mixers, resulting in significantly higher production efficiency. The applicable aggregate particle size range is expanded to 180mm, supporting the preparation of high-strength concrete, fiber-reinforced concrete, and other special concretes.

Uniformity control:

The composite motion trajectory eliminates mixing dead zones, resulting in low concrete dispersion and improved surface quality and structural strength. Suitable for high-grade concrete above C60, self-compacting concrete, and special mortars. Applicable to industrial production fields such as high-speed rail track slabs and prefabricated building components, meeting high homogeneity requirements.

Low wear:

The gap between the blades and the drum wall is adjustable, and wear-resistant parts (blades, liners) can be quickly replaced, reducing user operating costs.

Wide adaptability:

Customizable volumes (0.5-10m³) are available, supporting various working conditions such as dry mixing, wet mixing, and semi-dry mixing.

Intelligent and modular design:

Some models are equipped with hydraulic unloading, wear-resistant lining, monitoring systems, weighing systems, and high-pressure cleaning systems to achieve automated production. Supports multi-layer blade, frame, or butterfly mixer combinations to handle materials of different viscosities and process requirements.

Application scenarios of planetary concrete mixer:

- Construction engineering

Production of precast concrete components (precast beams, slabs, wall panels, stairs, piles).

Manufacturing of municipal components (cement pipes, manholes).

- Specialty concrete preparation

Processing of ultra-high performance concrete (UHPC), glass fiber reinforced concrete (GRC), and dry-hardened concrete.

Mixing of high-grade concrete and self-compacting concrete (SCC).

- Industrial applications

Mixing of materials in refractory materials, metallurgy, water glass, ceramsite, and other industries.

Processing of high-viscosity substances such as energy battery slurries, sealants, cosmetics, and food sauces (requires a dedicated planetary concrete mixer).